Ice Cream

Practical Action

popular flavouring, but producers should find out local preferences before deciding the range of

flavours to offer (see for example ice cream makers such as Ben and Jerry’s, makeicecream.com,

or flavour suppliers such as H. E. Stringer or other large producers for the range of possible

flavours).

Formulating an Ice Cream Mix

It is important that small producers understand how to develop new ice cream mixes to meet

changing customer demands. ‘Balancing’ the mix involves maintaining the correct balance

between:

Fat and sugar which controls the ‘fattiness’ of the product in the mouth.

Water and solids which controls the texture or hardness/softness.

The formulation of an ice cream mix should also take into account the cost and availability of

ingredients. Details of the method used to calculate the weights of each ingredient in a recipe

are beyond the scope of this Technical Brief, but details are given in Dairy Science and

Technology Education and ice cream recipes are available at http://makeicecream.com and

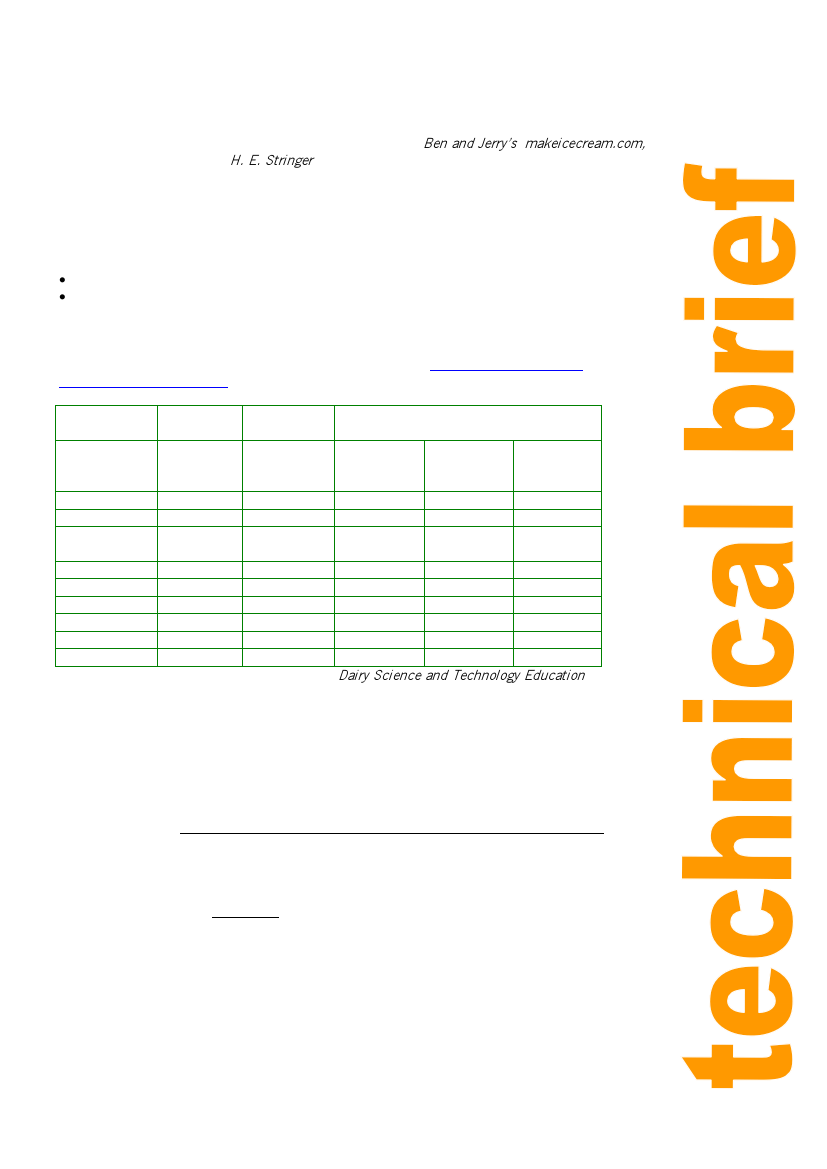

www.ice-cream-recipes.com. Examples of ice cream mixes are shown in table 2.

Low-fat ice Soft-frozen ice

Hard ice creams

creams

creams

Standard

Premium

Super-

brands

brands

premium

brands

Component

(%)

(%)

(%)

(%) (%)

Fat 3.0 - 8.0 10.0 - 10.0 10.0 - 12.0 12.0 - 15.0 15.0 - 18.0

Milk Solids-not- 13.0 - 11.5 12.5 - 12.0 11.0 - 9.5 11.0 - 9.5 11.0 - 9.5

fat

Sucrose

11.0 - 12 13.0 - 10.0 10.0 - 15.0 10.0 - 15.0 10.0 - 15.0

CSS

6.0 - 4.0 4.0 - 4.0

5.0 - 3.0

5.0 - 3.0 5.0 - 3.0

Stabilizer

0.35 - 0.15 0.35 - 0.15 0.35 - 0.15 0.35 - 0.15 0.35 - 0.15

Emulsifier

0.15 - 0.10 0.15 - 0.15 0.15 - 0.10 0.15 - 0.10 0.15 - 0.10

Water

66.3 - 63.7 64.0 - 63.7

64.0

62.0 - 60.0 <60.0

Total Solids

33.6 - 36.3 36.0 - 36.3

36.0

38.0 - 40.0 >40.0

Table 2: Mixes for ice creams (Adapted from: Dairy Science and Technology Education)

Production method

The general method for producing ice cream is shown in Figure 1.

The increase in volume of ice cream due to the incorporation of air is known as the ‘% overrun’,

and in commercially produced ice creams this varies from 60-100% or more. In some countries

there is a legal maximum of 120% overrun.

Overrun % can be calculated as follows:

Overrun % = 100 x weight of a given volume of mix – weight of same volume of ice cream

weight of same volume of ice cream

If, for example, 3.1 kg of ingredient mixture is needed to fill a container so that it is level with

the top of the container and then with 1.6 kg of ice cream, again level with the top,

the % overrun = 100 x (3.1 – 1.6)

1.6

= 100 x 1.5/1.6

= 93.75%

Because ice cream is sold by volume, the amount of air in the finished product has an important

effect on profitability. Small batch freezers (below) can only beat small amounts of air into the

mixture as it freezes, to give an overrun of 50% or less. Commercial freezers are more efficient at

incorporating air and overruns can be 100% or more.

3